Description

Model Number:Zoway-DWB10L

1. Compliance:CE Certified

2. Warranty:2 Year limited warranty with lifetime support

3. Delivery Time:In Stock

Email: imani@batterypackassembly.com

Tel:+86 13174506016

WhatsApp:

+86 18659217588

WeChat:18659217588

Email: imani@batterypackassembly.com

Introduction

The deionized water machine produced by our company is a high-purity water equipment made using the most advanced reverse osmosis process principle in the world. The raw water is filtered through three-stage pre-treatment. First stage: 5 micron PPF filter element; removes suspended solids and other substances larger than 5 microns in water. Second stage: Activated carbon adsorption filter element, removes residual chlorine, by-products, organic matter, etc. from the water. The third stage: 1 micron PPF filter element, removes suspended solids and other substances larger than 1 micron in the water. The water after the first three stages of pretreatment can meet the incoming water quality of reverse osmosis. It is pressurized by a high-pressure pump and enters the fourth-stage reverse osmosis membrane. Reverse osmosis membranes can remove more than 90% of ions and other dissolved solids. This greatly reduces the load on the subsequent ion exchange column, thereby reducing the number of replacements of the ion exchange resin. The fifth-level pure water column is treated with ion exchange resin. The conductivity of the treated water can reach 0. 1us/cm. The sixth-level pure water column is a TPF post-precision filter to completely remove traces of broken resin or impurities.

The entire water production process is fully automatic computer control. After turning on the power switch, the system automatically shuts down when the raw water pressure is low or the water outlet valve is closed, with automatic low-pressure protection and high-pressure shutdown.

An online water quality detector is installed in the water outlet pipeline, so the water quality can be known at any time.

Features

1. Reverse osmosis separation system: The combined filter element of this machine adopts a new type of reverse osmosis membrane separation system with scientific and technological achievements.

Deionization technology can pretreat and remove more than 90% of ions in water, reducing the load on the ion exchange column behind it and reducing operating costs by more than 70% compared with traditional deionization processes.

2. Low noise: This machine uses a low-noise diaphragm high-pressure pump with long service life and reliable operation quality.

3. Automatic control of the water production process, low pressure protection, and automatic shutdown of high pressure.

4. The ion exchange resin in the pure water column is easy to replace.

The main technical parameters

Product number | QJRO10L | QJRO20L | QJRO50L |

power supply | AC220V 50HZ

| AC220V 50HZ | AC220V 50HZ |

Operating Voltage | DC24V

| DC24V | DC24V |

rated power | 35W

| 40W | 70W |

Standby power | <3W

| <3W | <3W |

Rated water production | (10 liters/hour)

| (20 liters/hour) | (50 liters/hour) |

Incoming water quality (conductivity 25℃) | <200us/cm | <200us/cm | <200us/cm |

Outlet water quality (conductivity 25℃) | <0. 1us/cm | <0. 1us/cm | <0. 1us/cm |

Raw water pressure | 0.2-0.5MPa | 0.2-0.5MPa | 0.2-0.5MPa |

Install

installation steps:

1. Close the main tap water inlet valve, wrap the external thread of the 1/4-inch water inlet ball valve around the raw material tape and connect it to the inlet

At the side hole of the water inlet tee, wrap the raw material tape around the outer groove of the water inlet tee and connect the reserved G1/2-inch tap water pipe joint.

2. Because this machine adopts membrane separation technology, wastewater will be discharged during the water production process. Please drain the wastewater

Drill a small hole (6mm) in the pipe, and then insert the small wastewater drainage pipe into the wastewater pipe to facilitate the drainage of wastewater discharged from the machine into the sewer pipe, or connect the drainage pipe of the machine to the drainage ditch.

3. Use 6mm PE water pipe to connect the water inlet pipe, pure water pipe and waste water pipe. (Note: Adjusting ball valve Installed on the pipe of GB pure water outlet)

Schematic diagram of the connection pipe on the left side of the pure water machine. (When connecting, just insert the 6mm white tube into the interface hole)

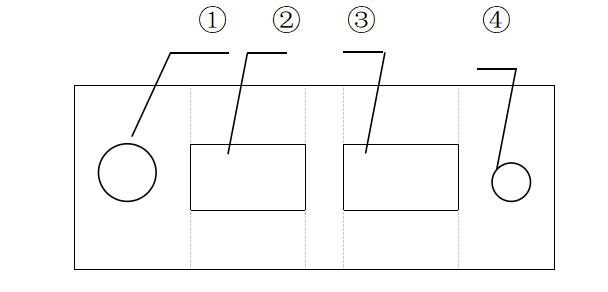

4. Deionized water machine panel component diagram

① Pressure gauge ② Water quality monitoring meter ③ Controller ④ Start switch

Note:

When ② the raw water pressure is less than 0.2Mpa, the water machine will automatically have low pressure protection and cannot start operation.

Debug

After confirming that the water connection is correct, you must also confirm:

1. Whether the power socket has power;

2. Confirm whether there is tap water supply.

Then enter the debugging of this machine as follows:

1. Open the main tap water inlet valve and the water inlet ball valve (the valve handle is in line with the valve body).

Outlet valve.

2. Insert the power plug into the power socket and turn the power switch ⑤ clockwise. At this time, the high-pressure pump starts.

After a few minutes, wastewater begins to drain out of the wastewater outlet. After about 90 seconds, the microcomputer automatically closes the door and flushes the solenoid valve. After a short period of time, deionized water will flow out of the outlet tap.

3. At this time, observe the outlet water quality display data of the conductivity meter. When the water quality reaches the standard (0.2us/cm)

Ready to use.

Normal use

1. Keep the water inlet valve open and the power supply turned on.

2. Turn on the power switch and open the deionized water outlet valve to take out the required deionized water. Just started

The effluent water quality may not meet the water quality you need. At this time, the unqualified water should be discharged. When the water quality meets the requirements, observe the online conductivity meter display. If the water quality conductivity you need is reached (0. 1-0.2 us/cm) and then take it, it will take about a few minutes. (If flushing is turned on for a long time, the conductivity of the outlet water still cannot be reduced and cannot reach 0.2us/cm, which proves that the pure water resin in the pure water column has failed and needs to be replaced and try again)

3. After use, turn off the power switch.

Unplug the power plug when not in use for a long time.

Special Note

1. The main pipe fittings of this machine are plastic products. Users must always observe their integrity during use.

2. This machine should not be placed in a place that is too humid.

3. The recommended intervals for replacing various filter elements of this machine are based on the national standards in the area of use.

The average indicator of tap water is statistically estimated. If the water quality at the actual place where the user uses it is significantly different from the average indicator, there will be a significant difference between the actual use status and the estimated period (such as premature blockage of the filter element, ion exchange If the filter element fails prematurely and the life of the RO membrane is shortened), the actual use status should be used as the basis for filter element replacement, and the local after-sales service department should be contacted promptly.

4. The high-pressure pump of this machine will produce vibration sounds when working, and its loudness is related to the raw water pressure, especially

When the source water pressure is lower than the rated inlet water pressure, the machine will vibrate due to the action of some air in the waterway.

5. For new machines, due to the presence of some air in the filter element, even when the water pressure is high, a relatively large amount of air may be emitted.

There is a loud vibration sound. After working for a period of time and all the air in the filter element and exchange column is exhausted, the vibration sound will return to normal.

6. If the raw water is short of water, there will be a buzzing sound and the system will automatically shut down. Please check whether the water inlet is turned on.

Check whether the valve or tap water is shut off.

Routine maintenance and upkeep

The first-stage filter element processes water capacity: 3000L or needs to be replaced every three months.

The second-stage filter element processes water capacity: 4000L or needs to be replaced every three months.

The third-stage filter element processes water capacity: 3000L or needs to be replaced every three months.

When the water output of the fourth-stage RO membrane decreases to a certain amount, the RO membrane needs to be replaced.

The replacement time of the pure water resin in the first, second and third level pure water columns should be based on the outlet water quality. When the conductivity does not meet the requirements, the resin needs to be replaced.

The first three-stage filter element is to ensure that the water inlet of the fourth-stage RO membrane meets the requirements. It can be replaced regularly or quantitatively as required.

Extend the service life of the fourth-stage RO membrane.

Ⅰ. Replacement of the first three-stage filter elements: Use the wrench (white) supplied with the machine to unscrew the filter barrel counterclockwise, put the new filter element into the filter shell, connect the filter shell to the joint, and tighten it with a wrench.

Ⅱ. Replacement of RO membrane: Remove the joint on the RO membrane shell, unscrew the upper end cover, pull out the RO membrane with pliers and other tools, replace the new RO membrane and tighten it.

Ⅲ.Pure water column (ion exchange column) replacement:

If the conductivity meter shows that the water output is unqualified, the resin in the resin column needs to be replaced. This polishing resin is disposable

Resin, not reusable.

When replacing, remove the water inlet and outlet connectors at both ends, unscrew the end caps, pour out the original resin, fill the new resin with pure water, tighten the caps, and connect them.

Troubleshooting

Fault phenomenon | cause of issue | Method of exclusion |

The machine does not move | Burnt fuse The power is not connected Raw water pressure is low or water is cut off The low-voltage switch is malfunctioning and cannot be connected to the power supply. Transformer burned out | Replacement insurance Check the power or original plug Check raw water pressure After connecting the raw water, measure its resistance and replace Measure its output voltage and replace |

The high-pressure pump works normally but cannot produce water | High pressure pump loses pressure The water inlet solenoid valve is faulty and cannot allow water to enter (neither pure water nor waste water). The pre-filter is clogged The check valve is clogged (there is waste water but no pure water) and the RO membrane is clogged. | Measure the water pump outlet pressure and replace it. Replace the water inlet solenoid valve. Observe the waste water and pure water, and replace the pre-filter element Replace check valve Clean or replace RO membrane |

The effluent water quality is unqualified | Even after long-term cleaning, it still fails and the resin fails. The ion exchange column has been used for too short a time | If the ion exchange resin fails, replace it. The RO membrane has failed, replace it. |

Product Images

Hot Tags: electrolyte filling°assing machine, suppliers, customized, wholesale, for sale, Pouch Cell Parts, Comprehensive Tester, Coin Cell Lab Fabrication Machine, Double Sides Automatic Spot Welder, Cylinder Cell Electrolyte Filling Pump System, Li Ion Battery Laboratory Fabrication Line

Previous: No Information

Next: Aluminum Laminated Film

2018-04-11 17:26:11

2018-04-11 17:26:11

+86-592-3926659

C329l1, Block BC, 1021 Houhai Avenue, Yuyi Community, Shekou Street, Nanshan District, Shenzhen